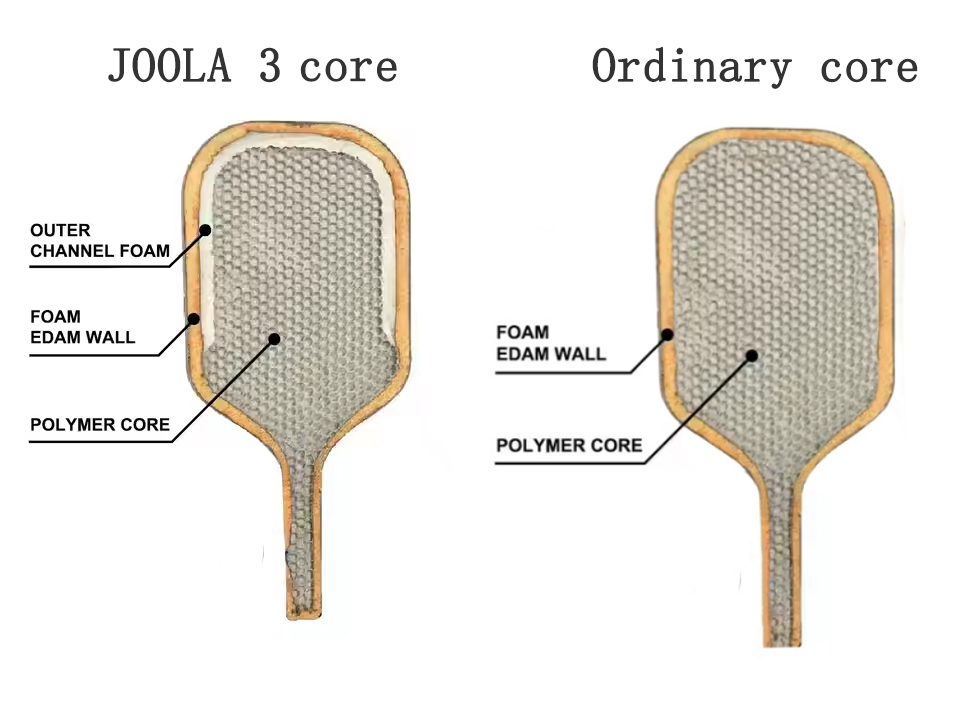

In addition to the frame materials, the core of the fourth-generation paddles has also undergone a transformation. Traditional honeycomb cores have been replaced with innovative foam materials, such as polypropylene and ethylene-vinyl acetate (EVA). These foam cores offer superior shock absorption and vibration dampening, reducing the risk of injury and providing a more comfortable playing experience. The foam cores also contribute to a larger sweet spot, making it easier for players to hit the ball with maximum power and accuracy.

Another notable aspect of the fourth-generation paddles is the design. Manufacturers are now focusing on creating paddles with a more ergonomic shape and grip, ensuring a comfortable and secure hold during play. The paddles also feature improved balance and weight distribution, allowing players to generate more power with less effort. Some manufacturers are even incorporating advanced technologies, such as variable thickness and textured surfaces, to enhance the performance of the paddle.

The manufacturing process of the fourth-generation paddles is a testament to the precision and expertise of the manufacturers. Advanced manufacturing techniques, such as injection molding and compression molding, are used to ensure consistent quality and performance. The paddles are also subjected to rigorous testing and quality control measures to ensure that they meet the highest standards of performance and durability.

The fourth-generation pickleball paddles have quickly gained popularity among players of all skill levels. Their superior performance, innovative design, and advanced manufacturing techniques have made them the paddle of choice for serious players and casual enthusiasts alike. Whether you're a beginner looking to improve your game or a seasoned pro seeking a competitive edge, the fourth-generation paddles offer a level of performance that is unmatched.

As the demand for pickleball paddles continues to grow, manufacturers are expected to continue investing in research and development to further improve the performance and design of their products. The future of pickleball paddles looks bright, with exciting advancements on the horizon. Whether it's new materials, innovative designs, or advanced manufacturing techniques, the next generation of pickleball paddles is sure to take the sport to new heights.