Dore Sports: Innovating with Purpose

To stay ahead in a competitive industry, Dore Sports has implemented several strategic changes and innovations in response to market trends and technological development:

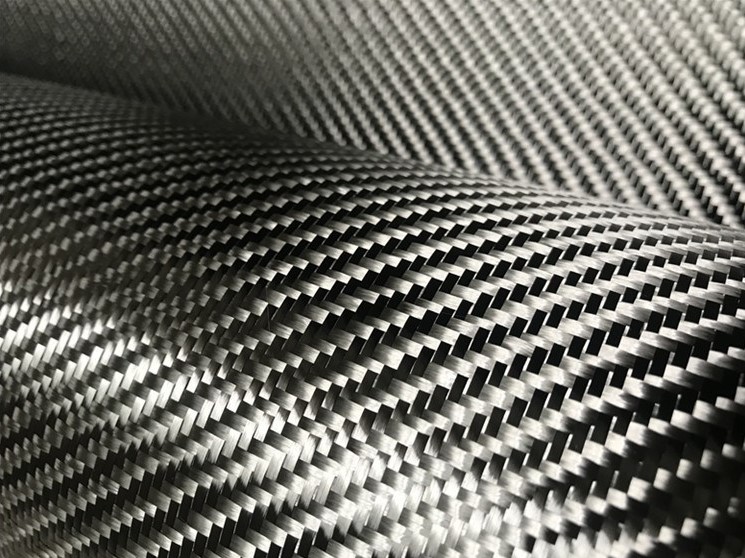

1. Multi-Material Integration

Dore Sports has developed paddles that combine carbon fiber faces with aramid (Kevlar) cores and TPU edge guards. This hybrid construction maximizes both performance and durability, offering a balanced paddle that caters to both power hitters and control-focused players.

2. Smart Mold Technology

Responding to the demand for consistency and quality, Dore Sports has invested in smart molding systems that ensure uniform thickness, weight distribution, and core integrity. This has allowed the company to produce paddles with tighter tolerance and better balance.

3. Sustainability Focus

Environmental responsibility is increasingly important to both consumers and manufacturers. Dore Sports now uses recyclable materials in their paddles where possible and is exploring bio-resin alternatives to reduce the ecological footprint of their production line.

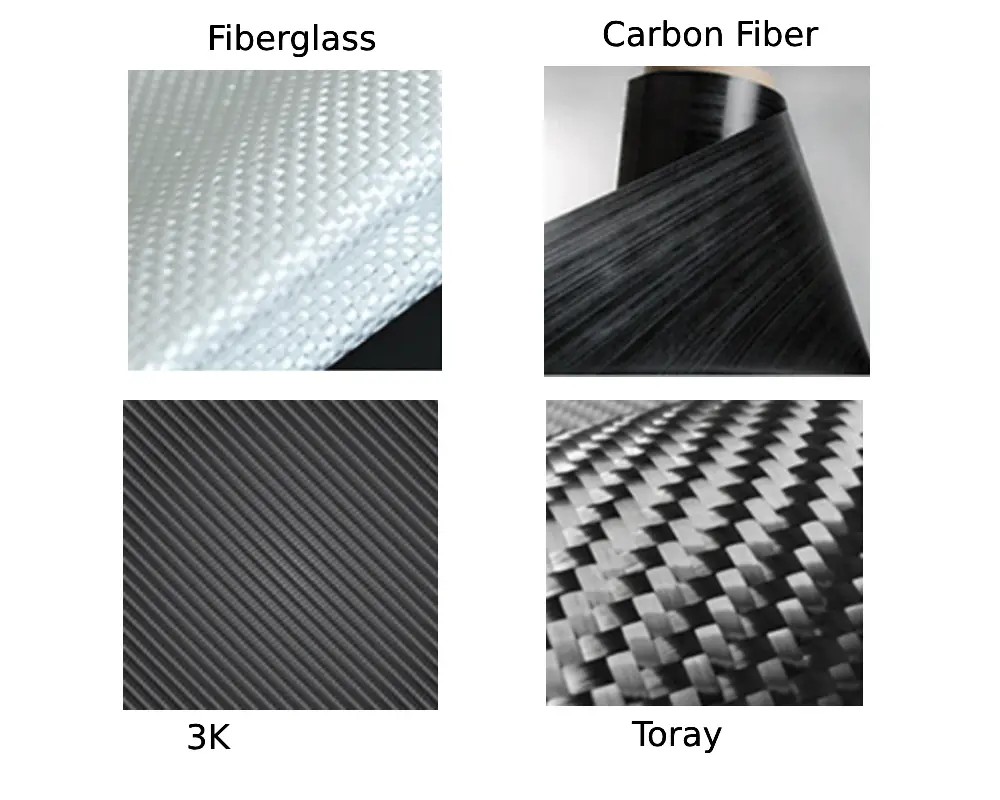

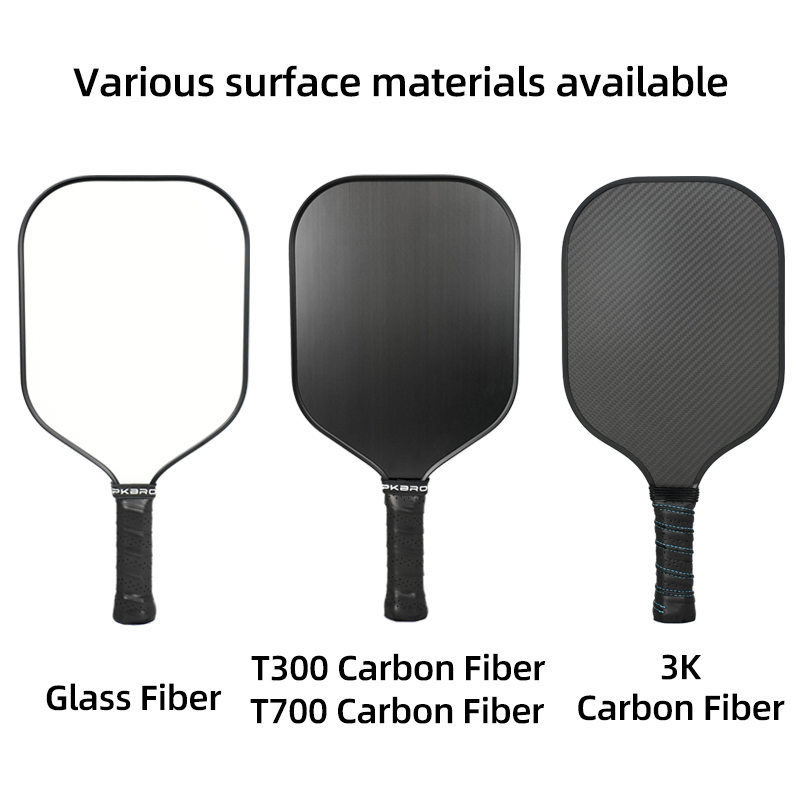

4. Customization at Scale

Recognizing the consumer desire for unique gear, Dore Sports has introduced a flexible customization platform where clients can choose materials, edge colors, grip styles, and even branding options—all without extending lead times. This mass-customization approach is powered by an upgraded digital design and sampling system launched earlier this year.

5. Enhanced R&D Collaboration

To remain on the cutting edge, Dore Sports has formed partnerships with material science labs and universities, testing new fiber weaves, surface textures, and core compositions. These collaborations aim to introduce paddles that not only look different but perform at an entirely new level.