The New Era of Paddle Crafting

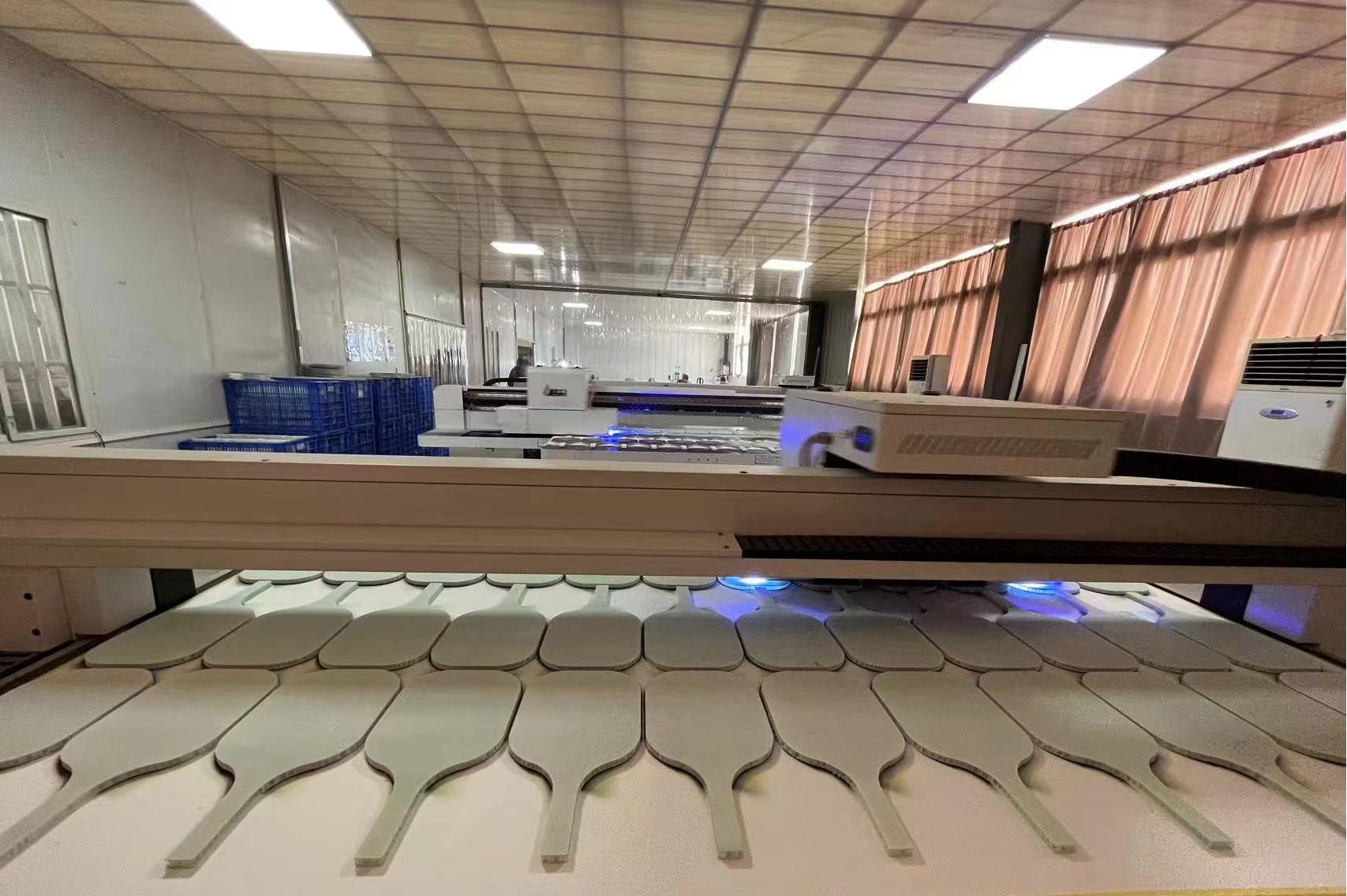

Gone are the days when basic printing and manual assembly defined paddle manufacturing. Today, processes like laser engraving, UV printing, and hot pressing molding have taken center stage, elevating the look, feel, and durability of paddles.

• Laser Engraving: With micrometer-level precision, laser engraving enables permanent markings and intricate detailing on both composite and carbon surfaces. Whether it's a brand logo, player name, or custom artwork, this process ensures sharp, fade-resistant visuals that add both functional and emotional value to the paddle.

• UV Printing: Offering unparalleled color vibrancy and high-resolution graphics, UV printing allows Dore Sports to deliver fully customized paddles with eye-catching designs. UV-curable inks dry instantly under ultraviolet light, improving efficiency while ensuring durability under heat, sweat, and friction. This technique is ideal for brands seeking premium visual impact without compromising quality.

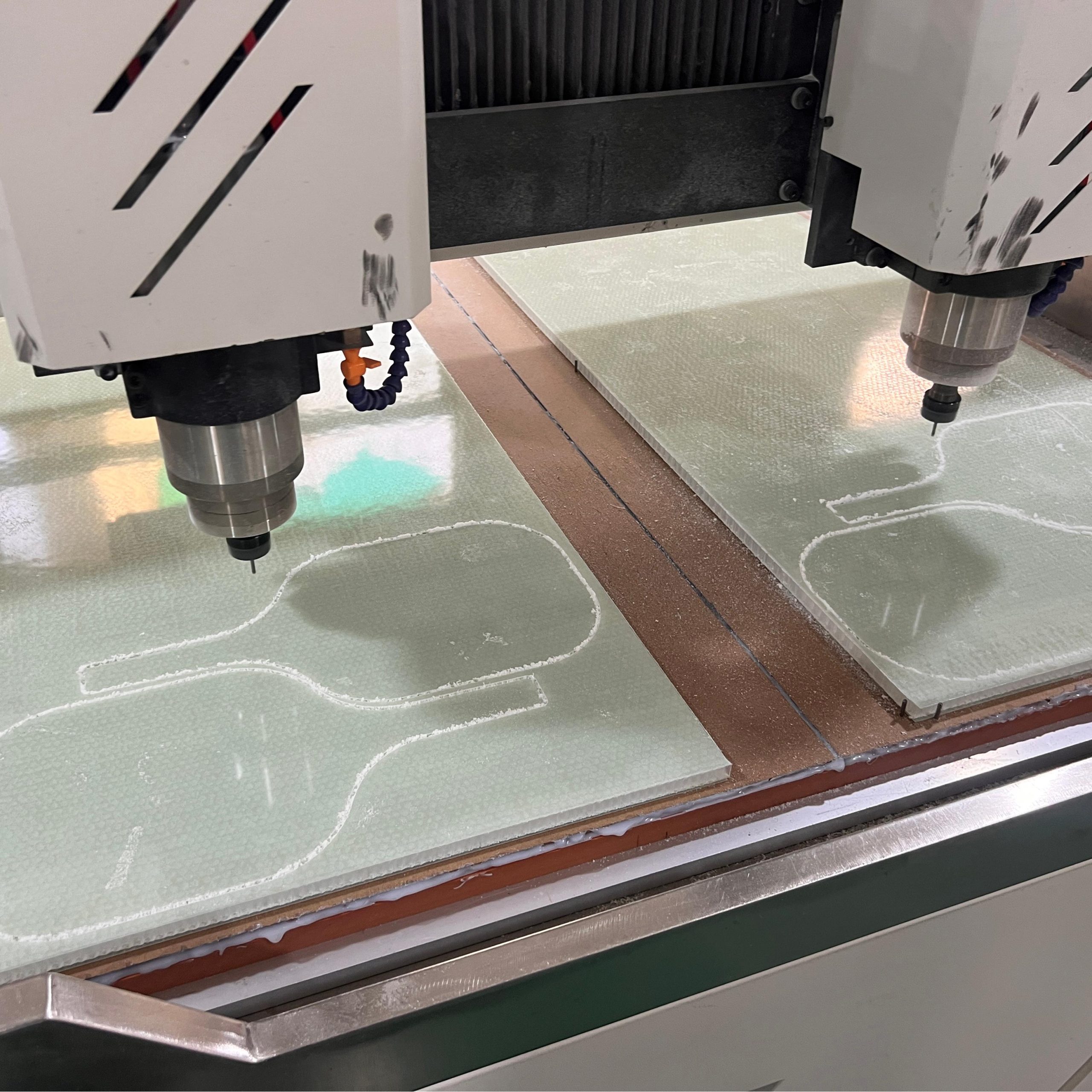

• Hot Pressing Molding: At the heart of Dore Sports' paddle performance lies its core forming process — hot pressing. This method applies high heat and pressure to laminate composite materials, ensuring a consistent surface, improved strength-to-weight ratio, and optimal energy transfer. Paired with CNC edge-trimming, this results in paddles that meet strict quality and precision standards.